Fatigue

Menu

Testing, Diagnostics, and Analysis

Many critical components see repeated cyclical loading during use. Although each load cycle remains below the static yield strength, fatigue can occur from progressive localized damage from fluctuating material stresses and strains. Unexpected and potentially catastrophic fatigue failures may result.

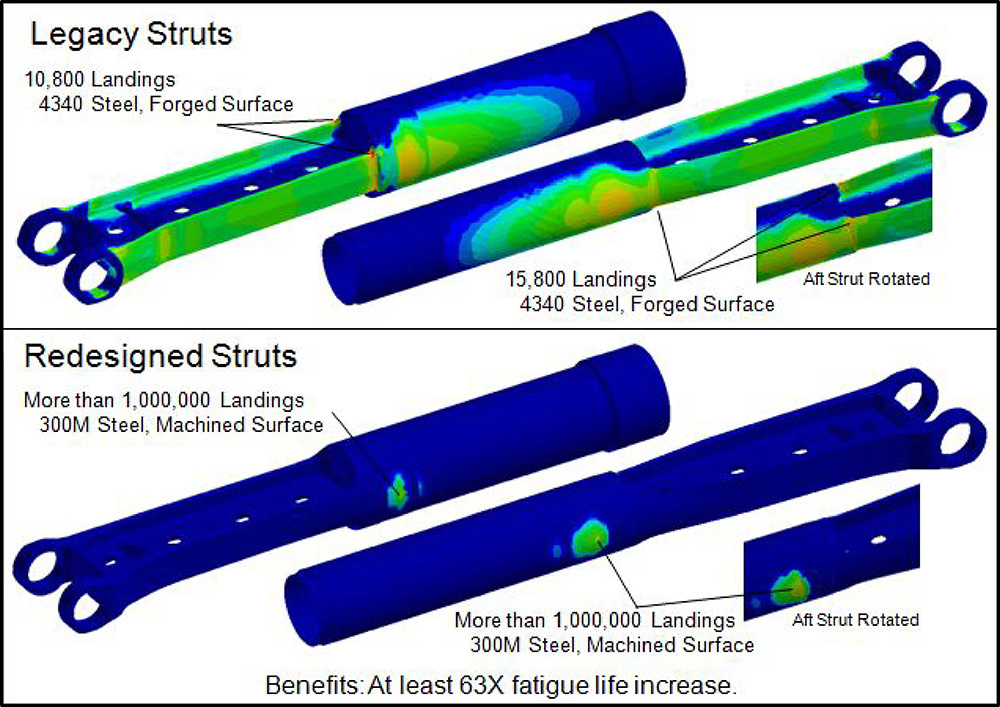

ES3 staff perform cutting edge finite element based fatigue analysis and simulation using nCode to support all new component designs/redesigns as well as predict failures for aircraft integrity and prognostic evaluations.

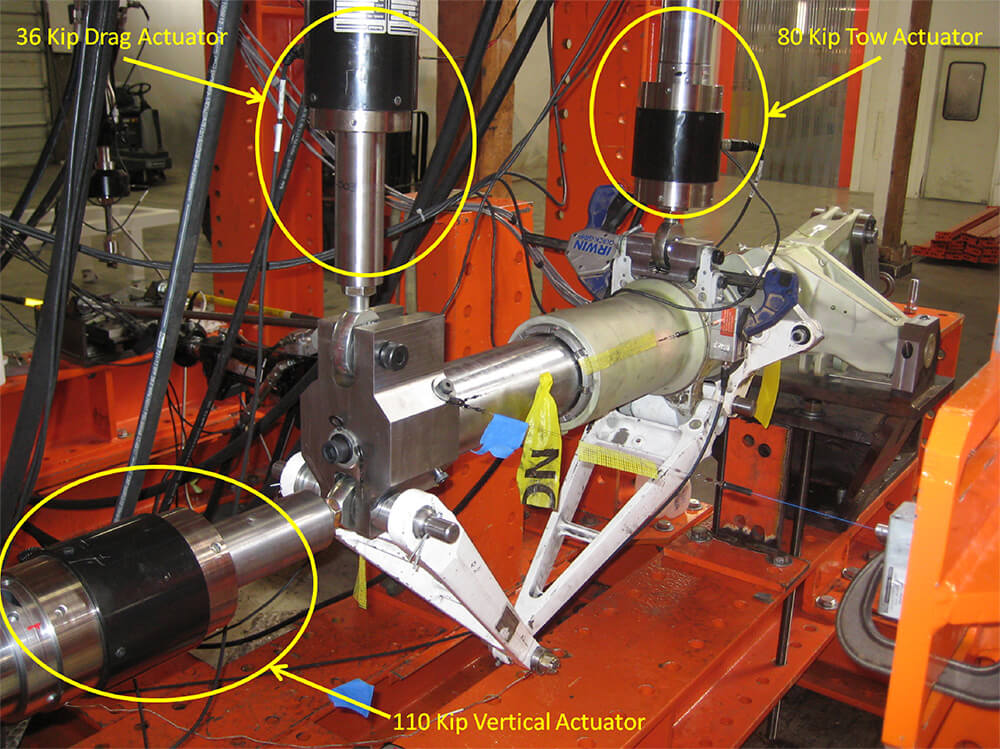

ES3 has also completed multiple fatigue qualification tests, including multi-directional loading, on critical landing gear components using our in-house test frame. ES3 also provides an array of diagnostic structural monitoring during aircraft operation to support usage-based fatigue life assessments and identify areas for component/system redesign improvements.