Advancing Aerospace Technologies for More Than 25 Years

2000-2025

ES3 is a niche engineering firm providing specialized design, development, and fabrication of products for aerospace and other heavy industry sectors. In 2025 we will celebrate our 25th anniversary. With immense gratitude, we thank our many customers who directly or indirectly sponsor the technology development responsible for our business growth.

ES3 has a purposeful business mission–to improve the performance, maintenance, and supply of mission-critical and safety-of-flight components while reducing the environmental impact of aerospace production processes and the hazardous exposures of aviation maintenance crews.

ES3 operates more than 300,000 square feet of customized office, laboratory, and production facilities in eight locations including San Diego, California, Clearfield, Utah, Warner Robins, Georgia, Midwest City, Oklahoma, Abilene, Texas, and Vienna, Austria.

Our Main Facilities

System Design and Redesign

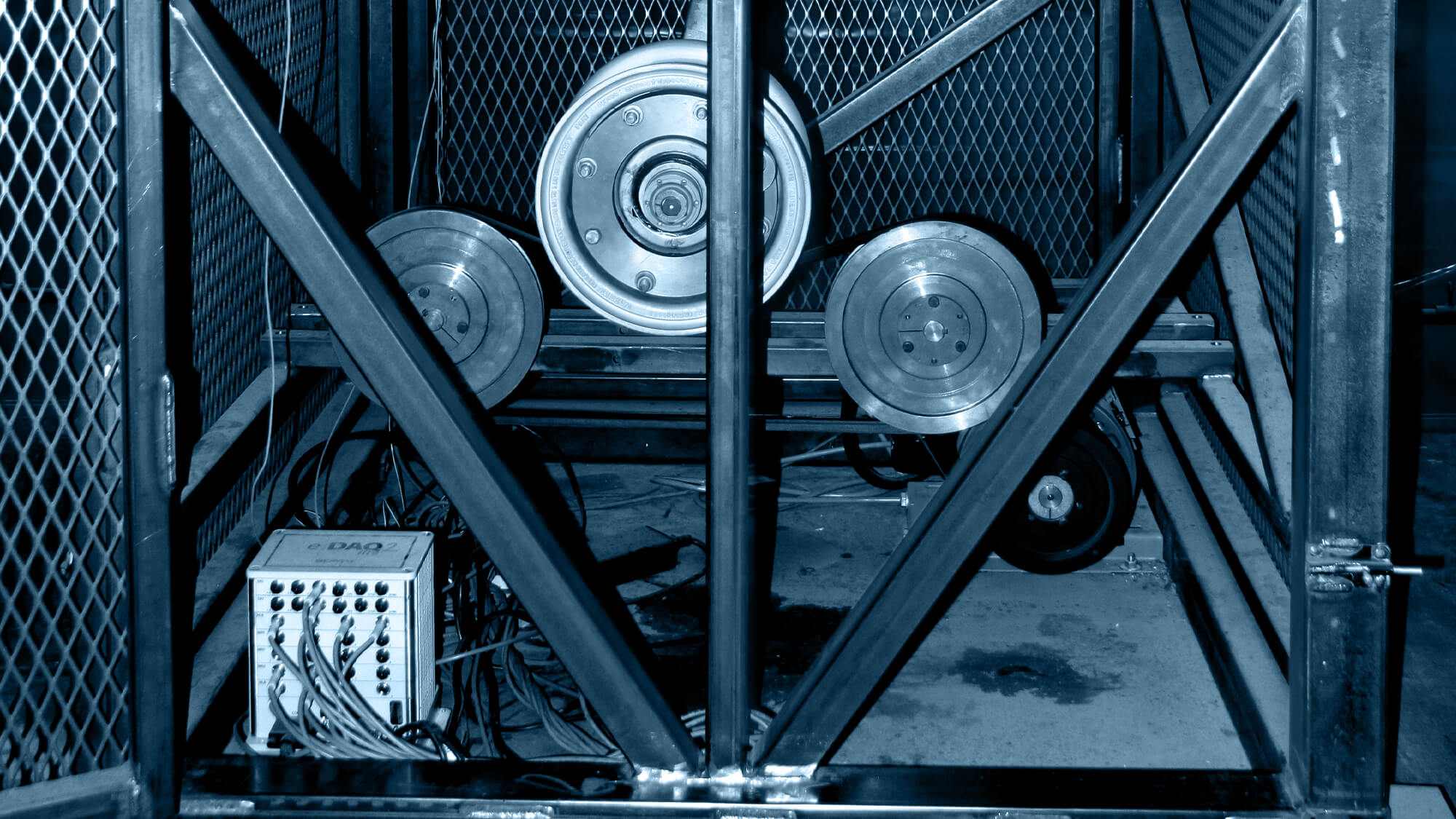

ES3 provides technical expertise in all aspects of landing gear systems research, test and evaluation, design and analysis, repair and maintenance. Our integrated team of mechanical engineers, electrical engineers, and logisticians performing research and development, test and evaluation, as well as performance qualification of new wheel, brake, and antiskid configurations. Additionally, ES3 provides aircraft operators with a full array of aircraft structural integrity support. And this is just the beginning. Click below to see our full array of engineering capabilities.

Environmental Initiatives

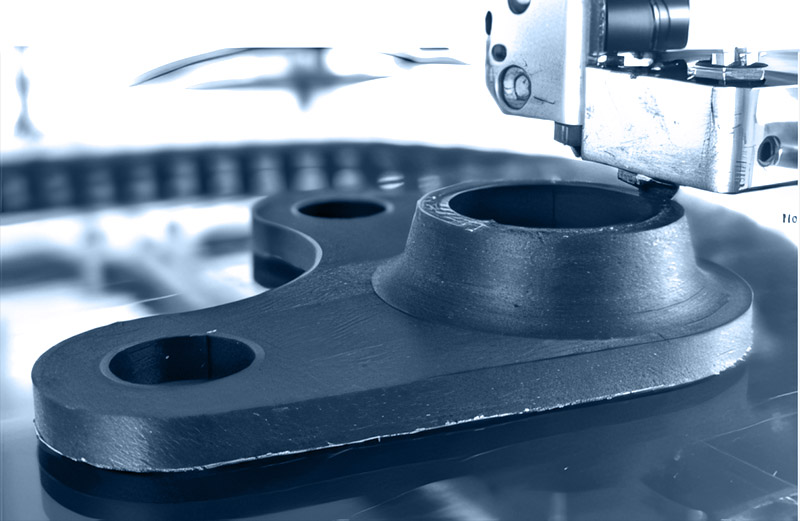

ES3 is determined to find Environmentally Preferred Alternatives to some of the traditionally corrosive ways for solving aerospace maintenance and repairs. ES3 maintains a state-of-the-art facility along with engineering and testing staff to define component-specific parameters and procedures for applying advanced surface solutions as alternatives to coatings such as chrome or cadmium. High Velocity Oxygenated Fuel (HVOF) coating processes, for example, are optimized and particularly well-suited for applications requiring wear, heat, and corrosion resistance or dimensional restoration-applications typical for aircraft structural components.

Testing, Diagnostics, & Analysis

Maintenance, Repair, & Overhaul

ES3 provides services to support military and commercial fixed-wing and rotary wing aircraft. Our sustainment services include modifications, upgrades, and enhancements, including structural and electrical modifications to aircraft as well as avionics upgrades. We also provide maintenance and repair, as well as logistical support for spares, aircraft systems, subsystems, and components.

F-16 Services

ES3 has a staff of highly experienced F-16 engineers who were formerly employed by the US Air Force and foreign militaries. Thus, ES3 is in a unique position as a private business to provide F-16 services to the US military, allied militaries, and private aggressor fleet operators. Our wing work includes wing overhauls, wing upgrades, and wing configuration changes. Our landing gear work includes inspections, dispositioning of maintenance and repair issues, and spare and repair part supply. Our structural work includes structural integrity inspection services, non-conformance evaluations, engineered structural dispositions, NDI evaluation and interpretation, supply of special repair tooling, and canopy sill longeron repair and replacement services.

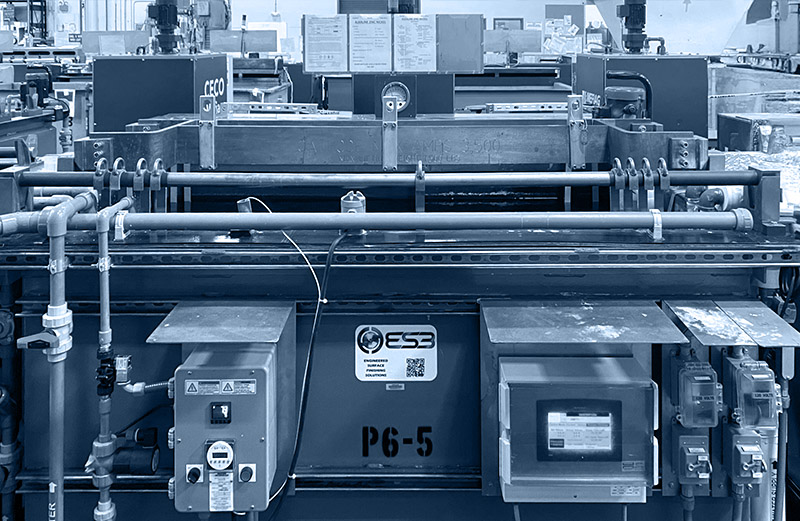

Surface Finishing

ES3 has a large contingent of Material & Processes (M&P) engineers who have been developing and implementing advanced surface finishing solutions for landing gear and other aerospace structures for more than 25 years. ES3 is a well-known and reliable source for developing highly-engineered electroplating, thermal spray, and plasma spray systems to meet the specific processing requirements of our customers. ES3 engineers will develop the system requirements, perform trade off studies, and custom engineer a surface finishing system for the end user while iterating with the end users to ensure the system will meet performance requirements. ES3 handles demolotion, fabrication, installation, and training, including all auxiliary system upgrades such as building modifications, material handling, electrical upgrades, and ventilation. Additionally, ES3 prepares all applications and secures all necessary environmental permitting.

MARS Solver

Since our inception in 2000, ES3 has been developing the MARS solver as a tool to enable the design of specialized materials. Today, MARS is enabling the design of aircraft structural components that are super light, aerodynamically optimal, and fabricated with the fast and low-cost Continuous Fiber AM (3D Printing) process. MARS uses a physics-based composite material model, DM4C—Discrete Model for Composites—that can explicitly simulate such AM fabrication phenomena as tow deposition and matrix polymerization with an ultra-high-fidelity description of bond formation including any manufacturing defects such as tow waviness, instabilities, porosity, and inter-filament debonding. DM4C has a proven track record of predicting the designed material performance at both the meso- and micro-scale level.