Additive Manufacturing

ES3 has a materials research and development (R&D) group with a proven track record of developing and implementing Additively Manufactured (AM) solutions for aerospace applications. ES3 develops, qualifies, and delivers AM systems for the repair of aircraft gas turbine engine parts. ES3 develops AM solutions for the new manufacture of metal aircraft parts as a replacement for castings and forgings with their typically long lead times. ES3 also develops new, highly engineered continuous fiber composites. In addition to our R&D work, ES3 is now taking orders for AM production runs for a host of aircraft and other parts which we are qualifying as acceptable AM replacements for parts made with traditional fabrication processes.

Continuous Fiber Composites

ES3’s work focuses on development of topology optimized efficient AM developed structures using recyclable thermoplastic and thermoset continuous fiber composite materials.

Additive Friction Stir Deposition

Using stirring friction AFSD is well-suited for both new fabrication and the repair of existing articles without ever melting the metal.

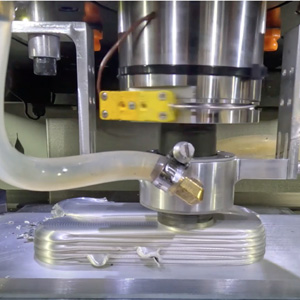

Directed Energy Deposition

DED forms a part or rebuilds a part by depositing material melted by focused thermal energy from a laser, or electron beam.