Civil Engineering

The Multiphysics Analyses of the Response of Structures (MARS) framework has been developed since the year 2000 to address the needs of practicing engineers as well as researchers in the field of structural engineering.

Many of the most significant construction materials (concrete, timber, polymers) are heterogenous at the relevant length scale, undergo aging processes resulting in micro-structural changes and are subject to pronounced time-dependent chemo-hygro-thermal processes.

MARS facilitates a variety of analysis problems such as but not limited to micro-structural analysis and fresh state printing.

MARS caters to the needs of structural engineers requiring complex nonlinear structural analyses considering cracking, cure-dependent material properties, time-dependent degradation processes and damage as well as concrete researchers studying the response of concrete and concrete elements in detail through virtual material and structural tests that account for the heterogeneity of concrete.

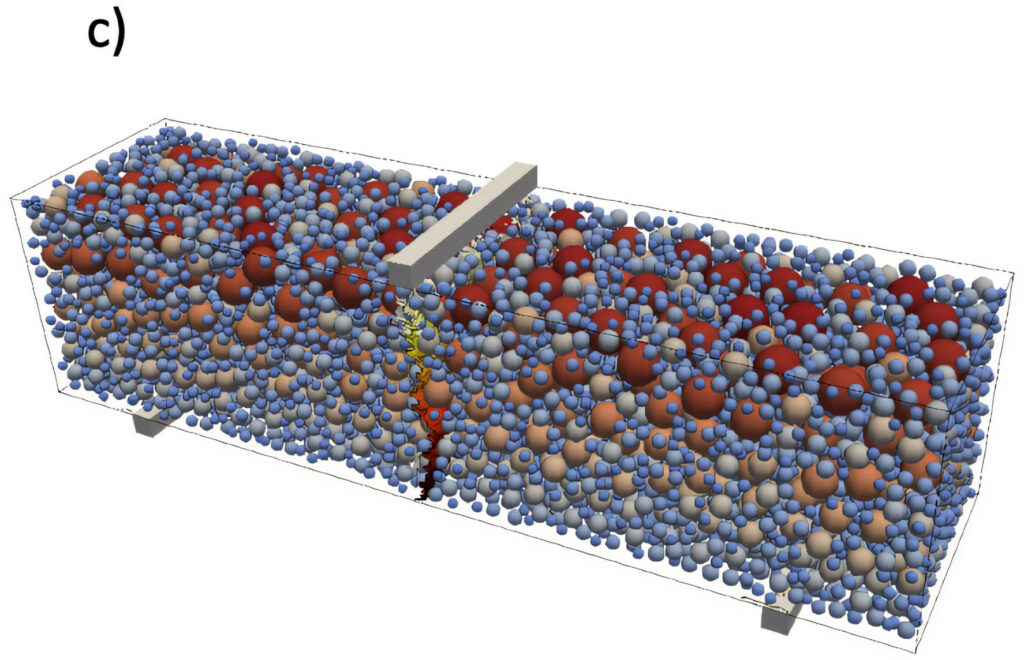

One of the biggest assets of MARS is its implementation of the Lattice Discrete Particle Model (LDPM) which has been refined over the last two decades and provides realistic predictions of the behavior of concrete under a range of loading conditions.

Lattice Discrete Particle Model (LDPM)

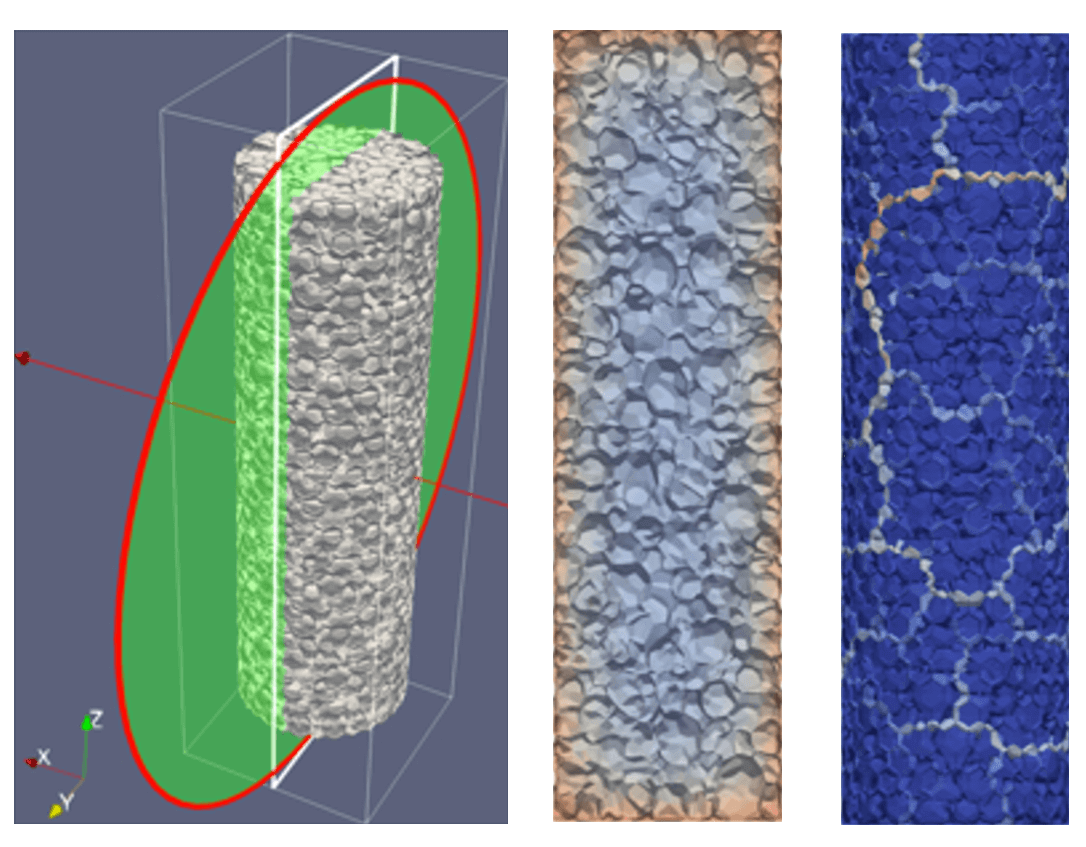

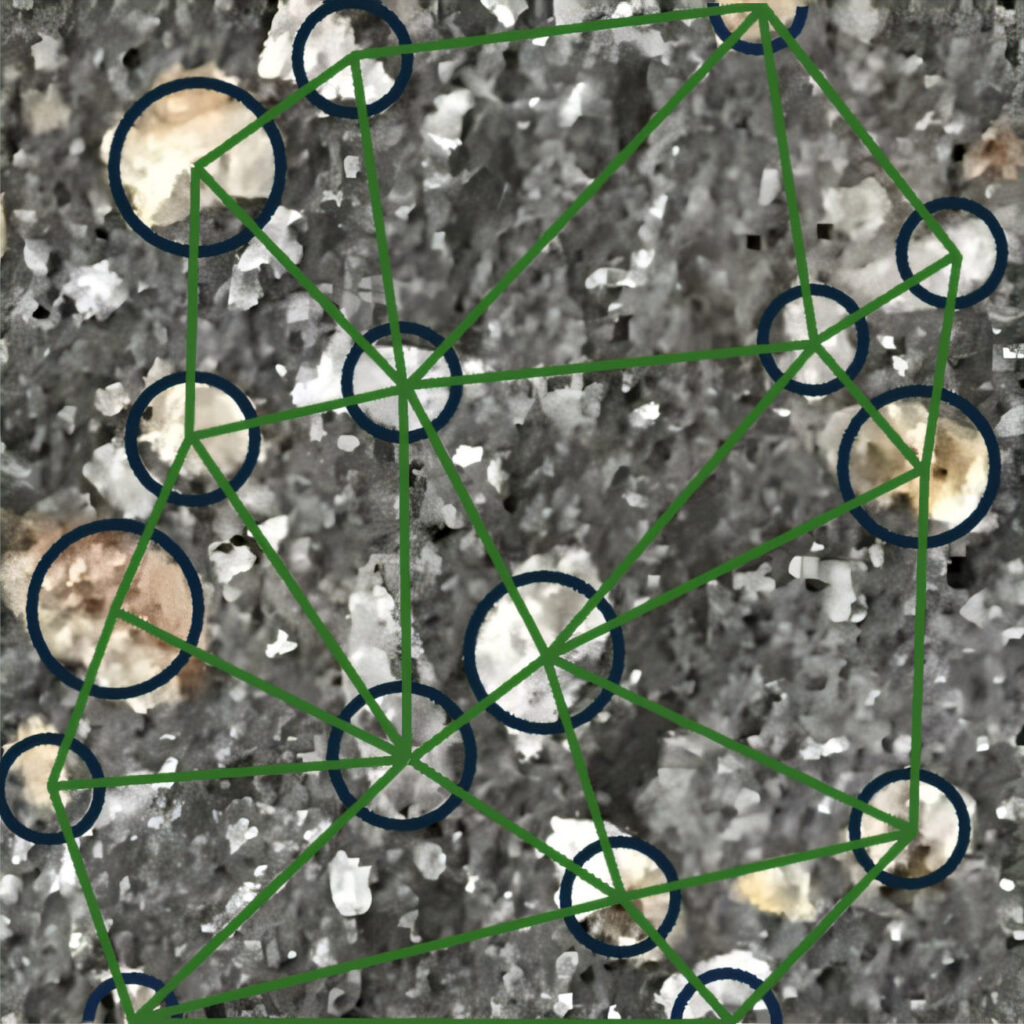

LDPM is a novel analytical approach for modeling the response of heterogeneous and granular materials, such as composite laminates, ceramics, concrete, gravels, and soils. The premise of the LDPM formulation is that most materials are not homogenous when considered at a sufficiently small dimensional scale (micro- and meso-scale). This heterogeneous character has a paramount relevance for the description of strain localization, crack initiation, and crack propagation, which, in turn, strongly influences the ultimate failure mode of a structural system. Continuum-based models, which homogenize material behavior, are inherently incapable of capturing the mesoscale interactions and as such become complex and inadequate in the failure range.

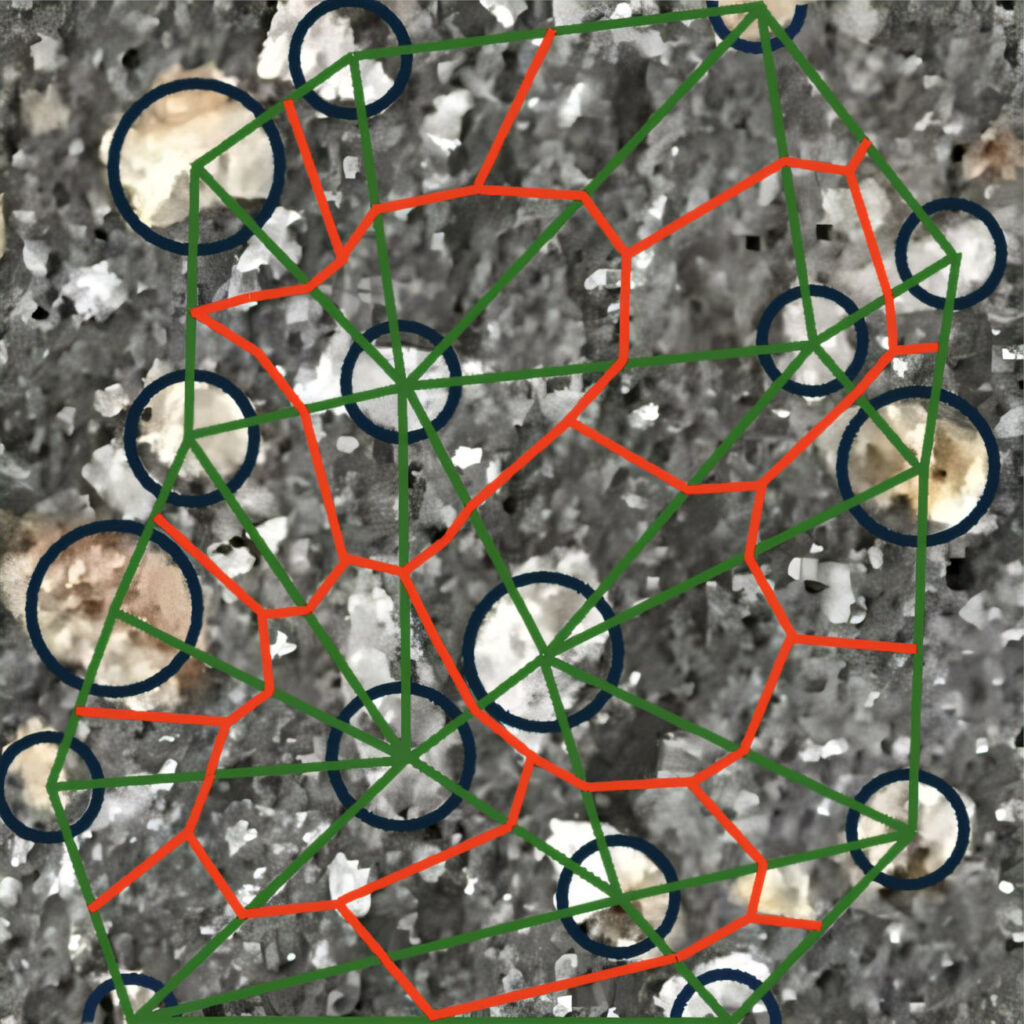

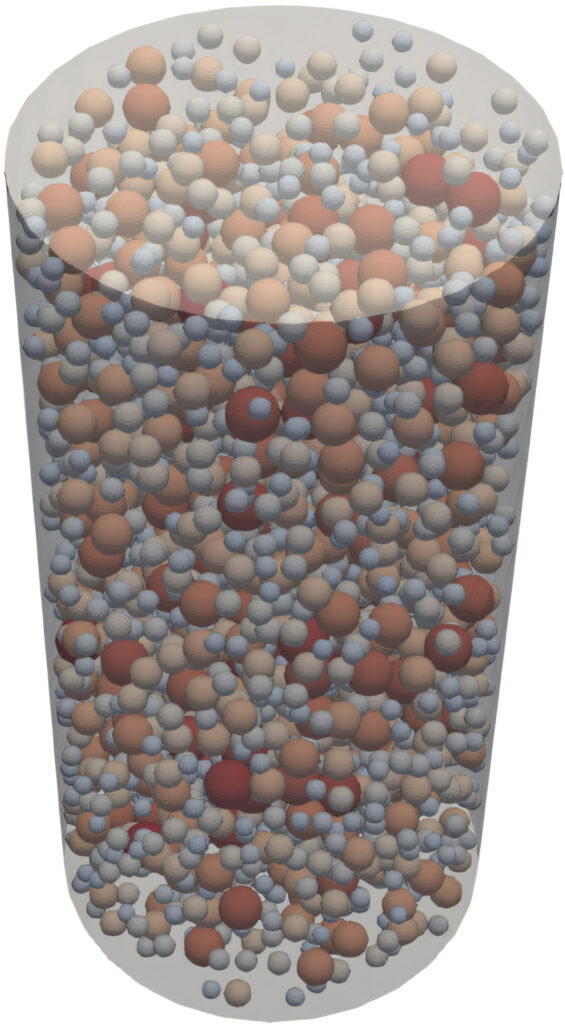

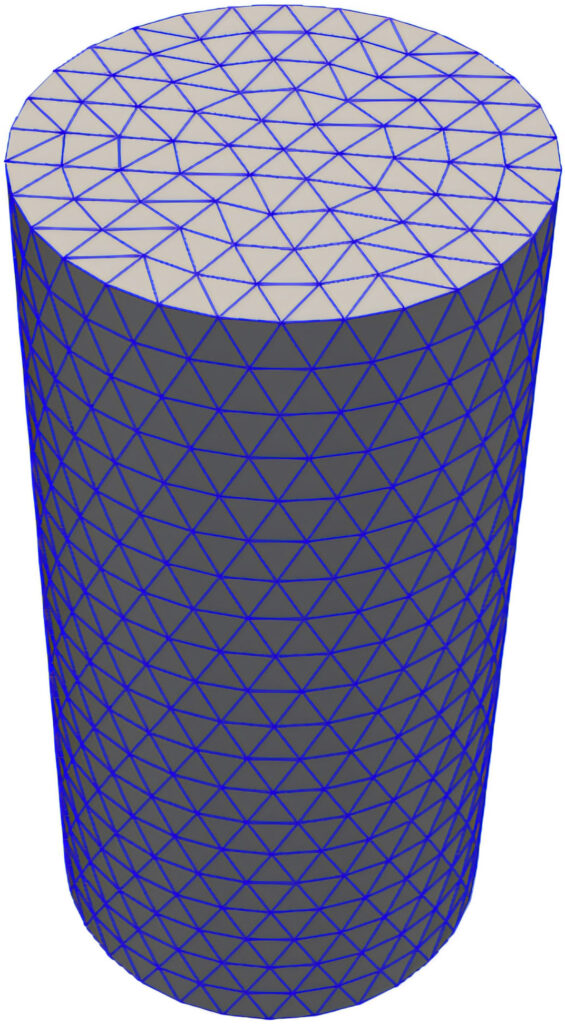

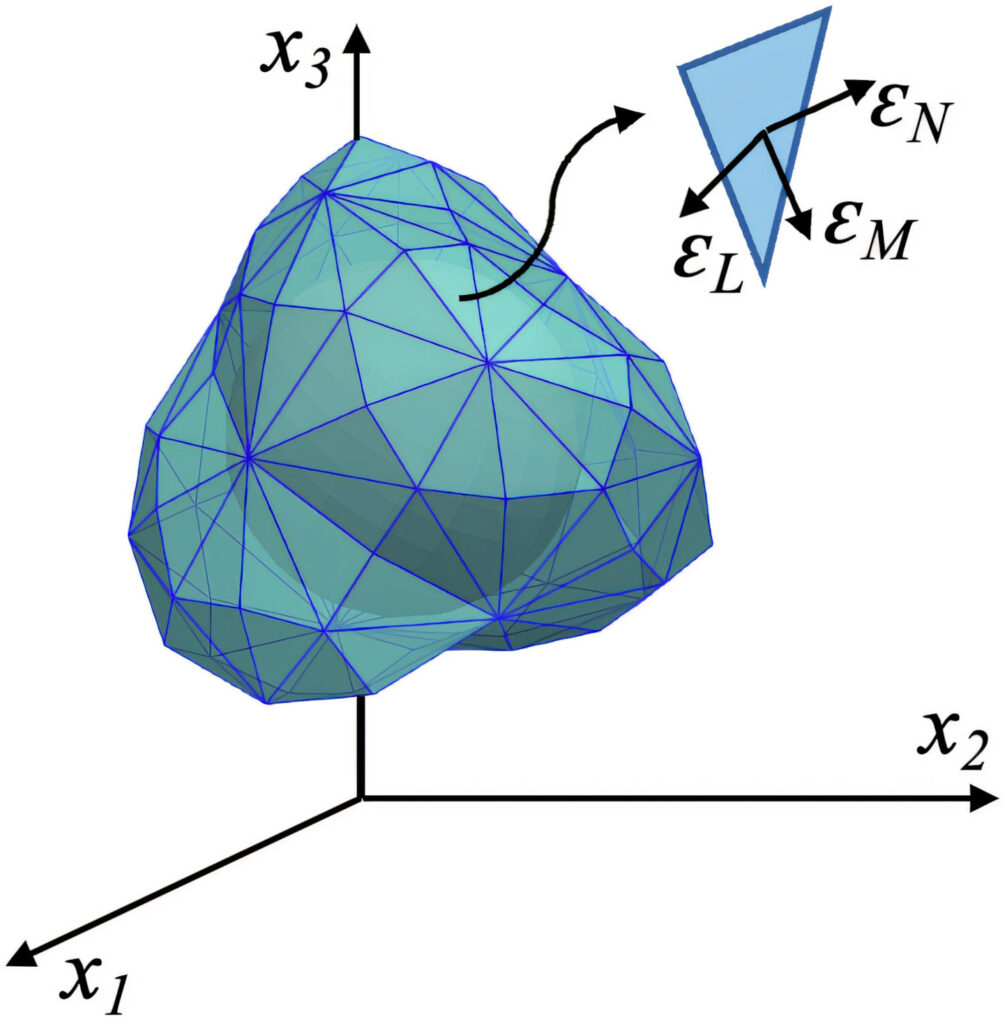

LDPM discretization scheme: (a) concrete meso-structure with coarse aggregates, (b) approximation of coarse aggregates by spheres, (c) tetrahedralization creating lattice mesh (green lines), (d) creating polyhedral cells, (e-g) renderings of discretization scheme in 3D, (h) example of a single polyhedral cell in 3D, bounded by triangular facets on which a vectorial constitutive law is evaluated

Response of Concrete

The most robust and computationally efficient implementation of the LDPM offers unparalleled predictions of the response of concrete subject to a number of loading situations including

- Unconfined compression with low and high friction along the loading platen

- Biaxial compression

- Hydrostatic compression and triaxial stress states

- Bending

- Torsion

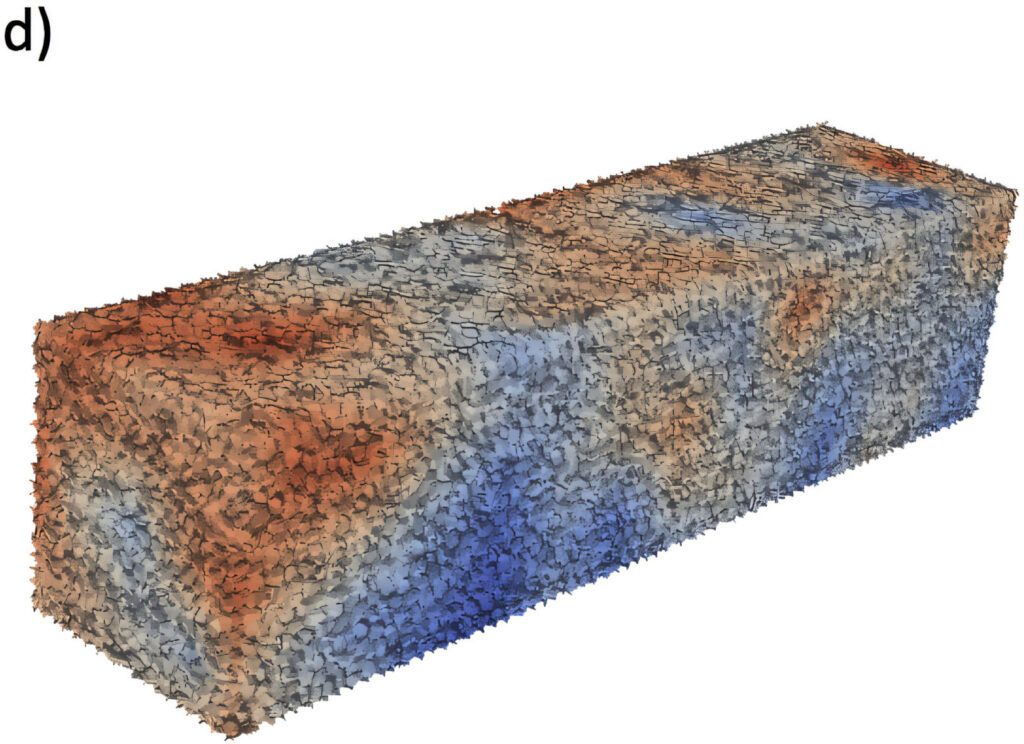

Unlike classical continuum-based models, LDPM provides realistic crack distributions and predictions of crack openings which take into account the actual size distribution of coarse aggregates. Furthermore, this feature makes it possible for computational simulations to predict experimentally observed scatter. This is accomplished computationally with MARS by running simulations on virtual samples with different particle configurations.

The excellent predictive capabilities of the LDPM framework was first demonstrated by Cusatis et al. (2011).

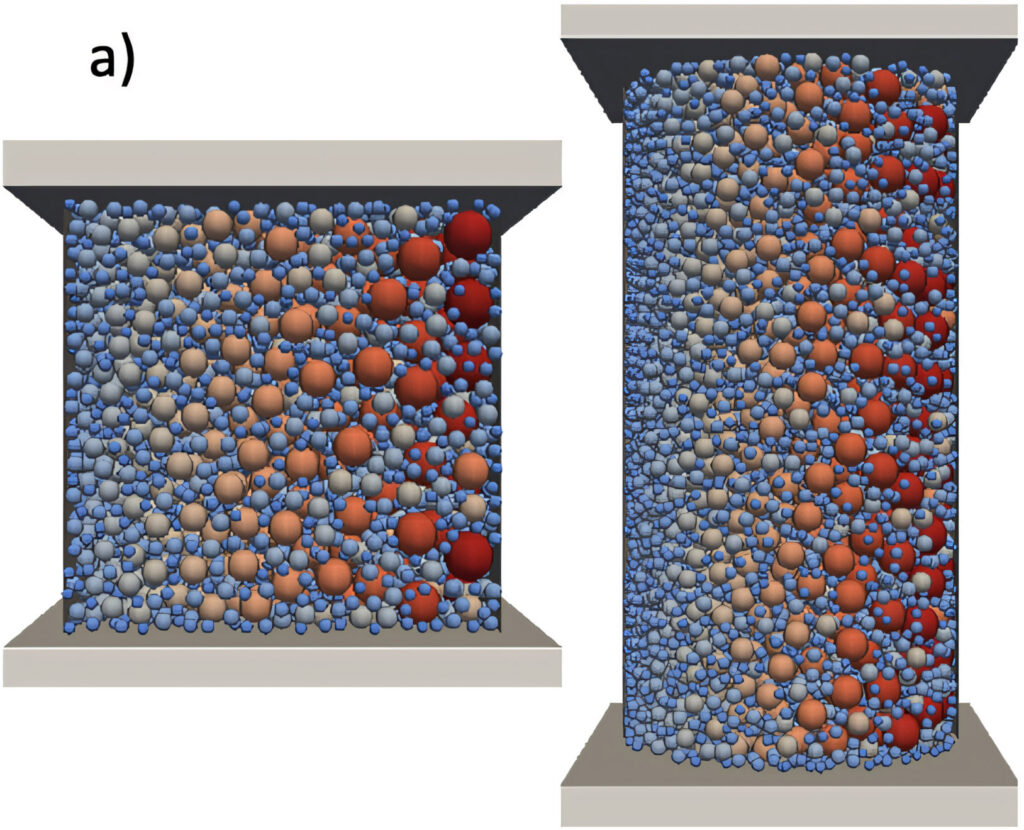

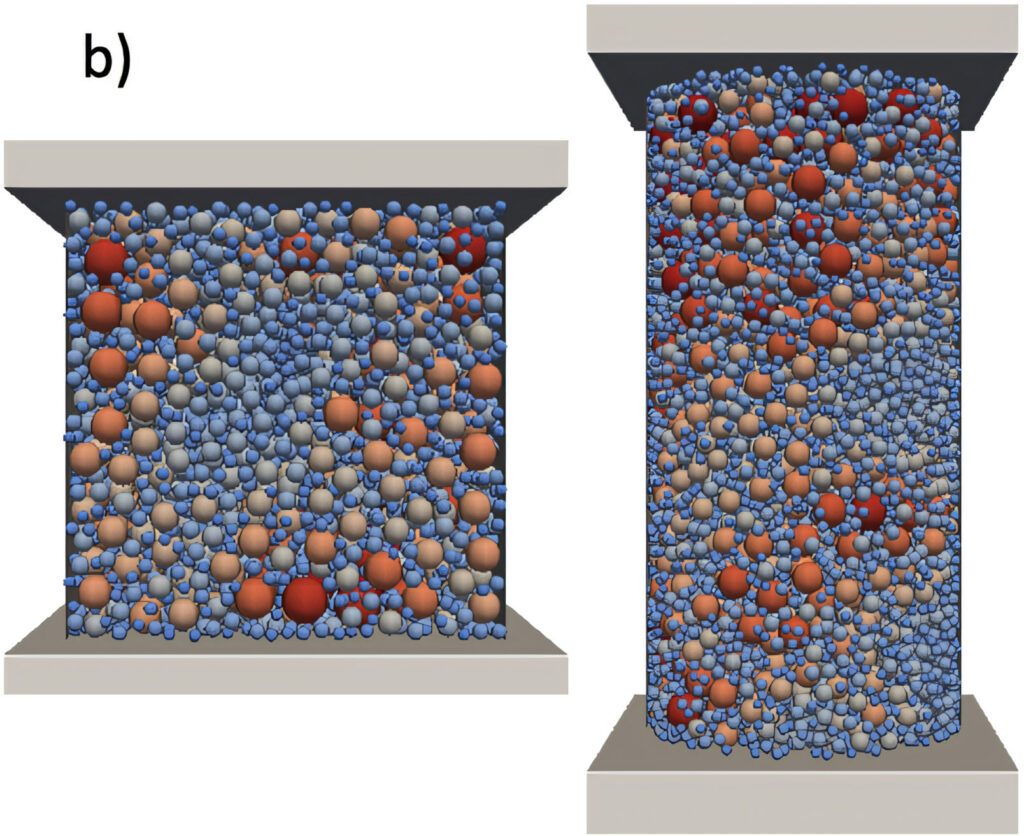

The following videos illustrate the typical failure of concrete in compression assuming low and high friction, respectively, between cube and loading platen, see Fig (a) and (b). Fig (c) shows a cylinder compression test while Fig (d) and (e) show a three point bending tests (D = 200 mm) with notch. Finally, Fig. (f) and (g) finally demonstrate the cases of biaxial (k = -1/-0.52) and triaxial compression (200 MPa confinement pressure), respectively. All figures correspond to simulations validated against experimental data.

Fiber-reinforced Concrete

In addition to reproducing the placement and distribution of coarse aggregate pieces, MARS also supports simulations with discretely placed fibers. The transition from post-peak softening to strain hardening can be predicted by varying the volume fraction of discretely placed fibers. Furthermore, directional effects that emerge during casting (preferential 1D direction in beams due to the flow of concrete, preferential in-plane orientation of fibers in shotcrete) can be virtually reproduced in order to study consequences on effective macroscopic response and in turn structural response.

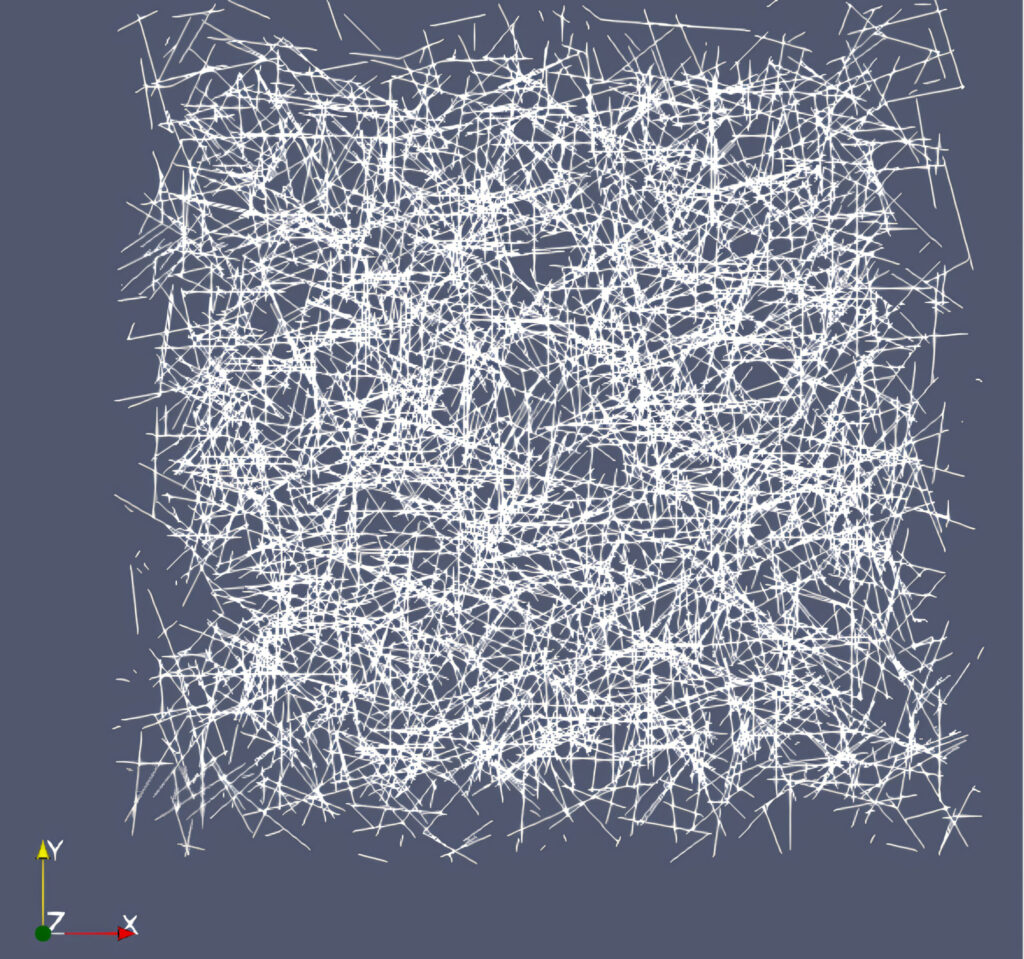

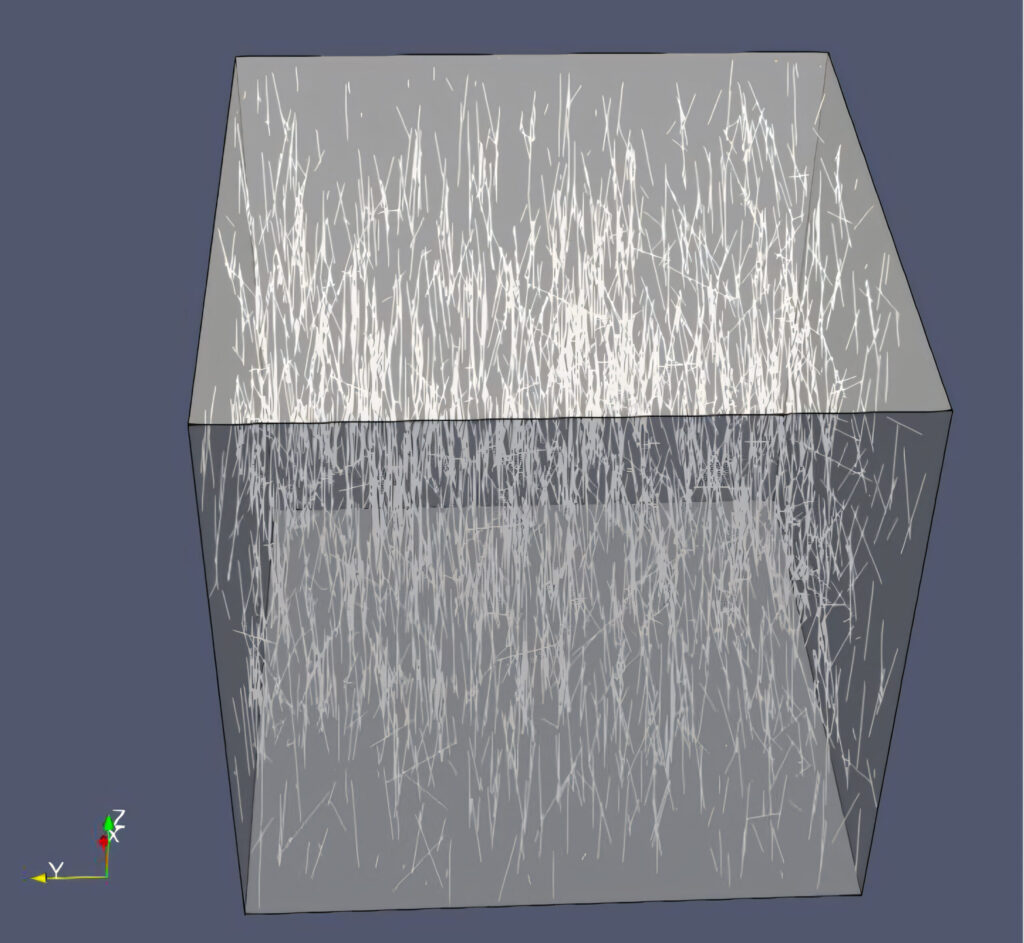

The left figure shows the case of an isotropic fiber distribution and orientation while the right figure demonstrates a preferential in-plane fiber orientation (here vertical) as relevant e.g. for fiber reinforced shotcrete applications.

Through the coupled multi-physics framework it is possible to consider the visco-elastic nature of polymer fibers or their temperature dependent stiffness as demonstrated in Del Prete et al. 2021 and Mishra et al. 2024

Spatial Variability

The optimal design and manufacturing of additively manufactured (composite, 3DPC) structures requires extensive parameter explorations to identify tradeoffs between manufacturability and performance, along with correcting possible issues before production. Traditionally, this process requires extensive physical trial and error resulting in slow product development, large costs, and a significant increase in the time from conception to qualification. MARS enables the Digital Engineering (DE) of the build process. Using digital data instead of experiments allows for the identification of possible problems early in the project when costs for corrective measures can be hundreds of times lower than after production has started. At the same time, digital manufacturing allows one to explore various combinations of manufacturing parameters that lead to optimal quality and repeatability in a short amount of time.

Cement hydration and temperature rise

Concrete is an aging material the properties of which change over time due to progressing hydraulic and pozzolanic reactions. Next to evolving mechanical properties the exothermal curing reaction releases heat and drives time-dependent deformations such as thermal expansion and hygral shrinkage due to self-desiccation and drying.

The former is especially important in mass concrete structures found in a number of applications.

MARS offers coupled hygro-thermal-chemical (HTC) simulations of OPC and concretes with blended binder systems considering e.g. cement hydration, silica fume polymerization. It is possible to predict the parameters describing the reaction kinetics from composition information of the binder using CEMHYD3D through the Onyx framework

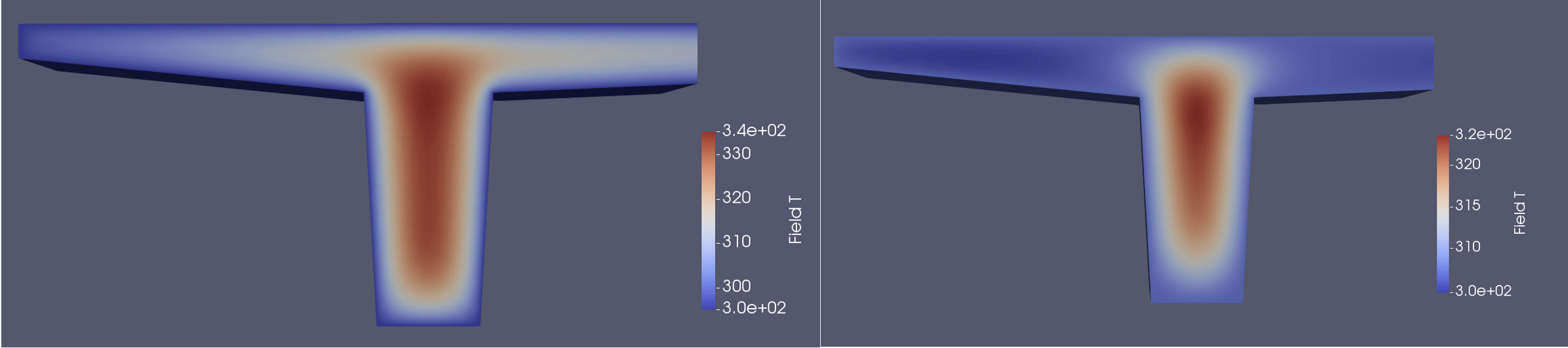

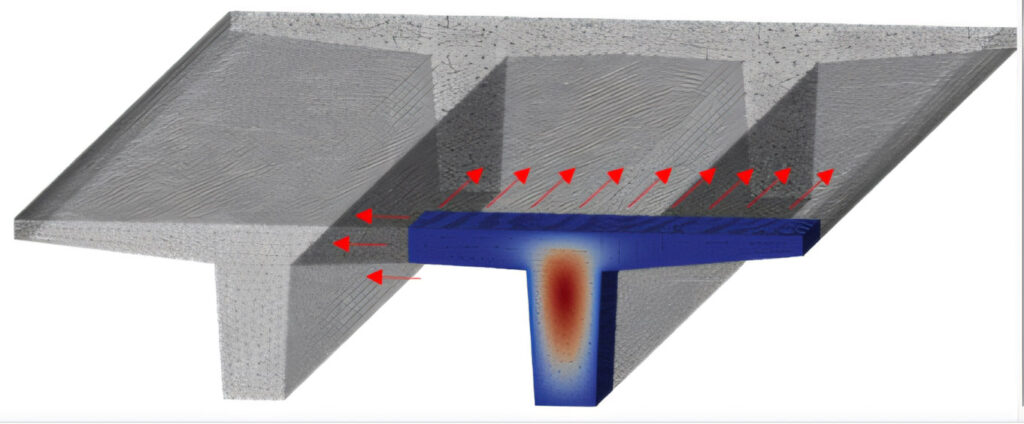

HTC simulations are available either in a traditional FEM framework for computationally efficient 3D simulations of large structures (see below, also with exploitation of symmetry and continuity) or by employing novel lattice flow (LFE) elements which form a network of transport conduits that is dual to the mechanical LDPM mesh. The latter offers unprecedented possibilities in linking the multi-physics analysis with mechanical analysis taking into account cracking.

3D hygro-thermal analysis of large structures with the option to exploit symmetry and knowledge about zones with predominantly 2D behavior (left); Humidity field in a curing concrete cylinder modeled through FLEs (right) as a basis for virtual material testing.

Hydration-degree Dependent Response: Drying and Autogenous Shrinkage

Concrete is an aging material the properties of which change over time due to progressing hydration. Realistic predictions of e.g. cracking risk at early age in mass concrete structures or in restrained concrete elements such as walls requires the use of spatially variable mechanical properties which are functions of the local hydration degree.

Drying and Autogenous Shrinkage

Several research papers have been published showing the excellent predictions of drying shrinkage and autogenous shrinkage driven by a coupled multi-physics analysis. The results not only agree in terms of global deformation history but especially regarding the predicted crack patterns which are impossible to obtain with standard finite element approaches.

Basic & Drying Creep, and Tertiary Creep

The consideration of creep in structural analyses is possible by utilizing different rheological models ranging from single Burger elements to Kelvin and Maxwell chains.

For concrete structures, the widely established Micro-prestress Solidification (MPS) Theory is available which can be coupled with hygro-thermal-chemical (HTC) analysis to obtain the multi-physics fields that drive solidification and micro-prestress.

In combination with a rate-dependent damage model, tertiary creep i.e. creep rupture problems can be successfully predicted.

Alkali-Silica-Reaction (ASR)

MARS is able to simulate the gel formation and resulting local expansion of alkali-silica reaction the lead to cracking and macroscopic strength reduction, see Alnaggar et al. (2012)

Autogenous Self-healing

Recent work by Cibelli et al. (2022) showed successfully the capabilities of the M-LDPM framework to capture the two-coupling between cracking and transport on one side but also the possibility to seal and mechanically heal cracks through autogenous self-healing.

Chloride ingress

The ability to simulate the ingress of aggressive agents such as chlorides was demonstrated by Cibelle et al. (2023).

Shear failure of prestressed concrete beams

The performance of prestressed structural elements at any given age depends on the actually present level of pre-stress which in turn is affected by a multitude of time-dependent processes such as hygral shrinkage of concrete, creep of concrete, relaxation of the prestressing steel.

Additionally, the mechanical properties evolve with the hydration degree, thus increasing strength and stiffness.

The Multiphysics Analyses of the Response of Structures (MARS) framework in combination with LDPM is ideally suited to predict the age-dependent failure load of such structural elements.

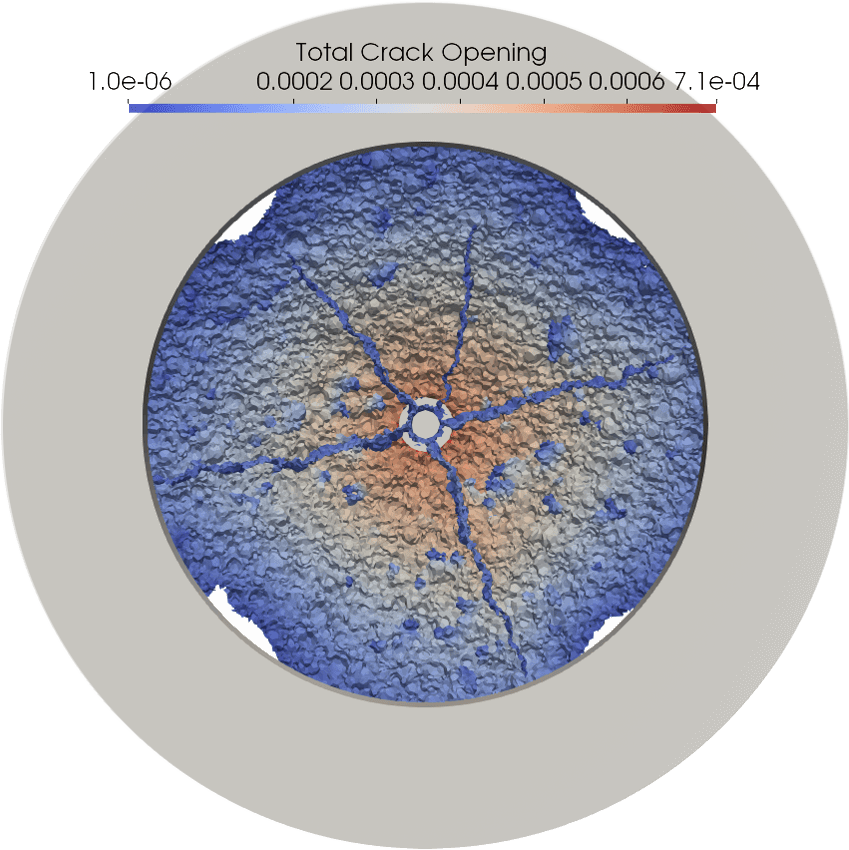

Concrete cone failure

The performance of anchorages to concrete is a rather specialized research field, yet crucial for fast and modular construction as well as structural strengthening and rehabilitation.

While typical concrete elements quickly reach a length scale at which resolving individual aggregate pieces is no longer necessary for most problems, this is typically not the case for local problems such as anchorages to concrete with a length scale similar to the dimensions of coarse aggregate pieces.

The unique capabilities of the LDPM available within MARS allows high fidelity simulations of anchorage failure that closely resemble experimental results, both in terms of predicted capacity, failure modes and resulting cone shape.

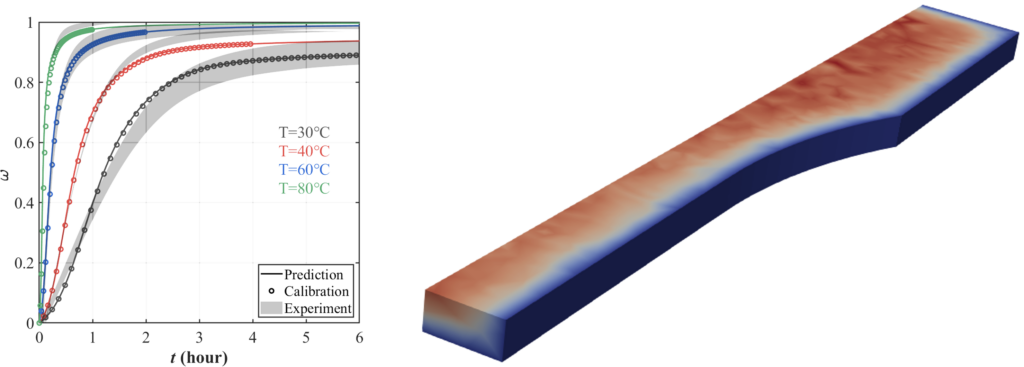

Cross-linking reaction in structural adhesives

The mechanical performance of a thermosetting polymer (e.g. used for post-installed adhesive anchors or FRP strengthening) also depend on an exothermal curing reaction which is also dependent on ambient conditions. It is, thus, relevant to predict the curing reaction in order to be able to predict the time until a sufficiently high curing degree is reached and the anchor can be loaded safely.