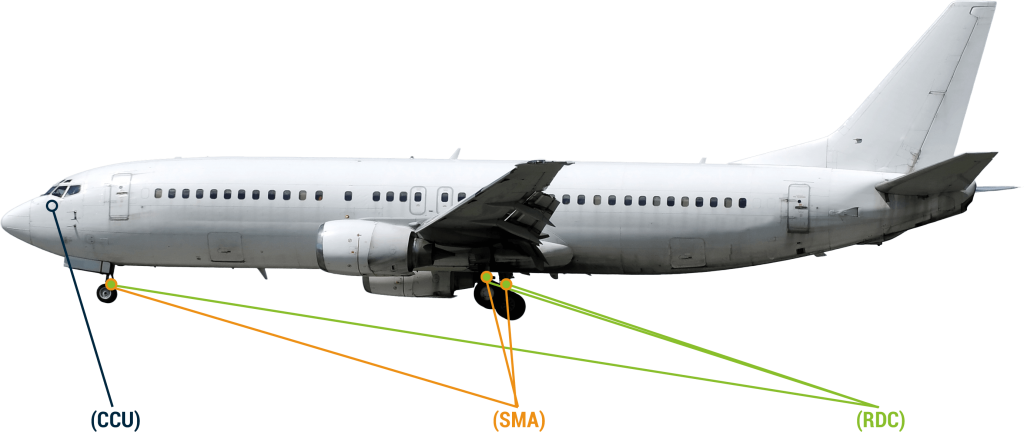

Landing Gear Diagnostics and Prognostics

Structural Health Monitoring Systems

Since 2012, ES3 has been developing landing gear Structural Health Monitoring Systems (SHMS) in collaboration with the US Navy, US Air Force, commercial operators and an OEM. Today, ES3 has successfully tested our system on four fixed wing and rotorcraft platforms. We have performed qualification tests, completed flight test/certification on one aircraft, and delivered production units that are currently fielded and performing well on operational aircraft. The ES3 SHMS is custom configurable to provide and display such conditions as:

- Aircraft/Rotorcraft Gross Weight

- Aircraft/Rotocraft Balance

- Conditioned Based Maintenance

- Strut Servicing

- Hard Landings

- Brake Temperature Monitoring

- Historical Data (via display or data output)

The ES3 SHMS requires no modification to the landing gear strut assemblies. It can be retrofit onto existing aircraft. The control unit has ARINC 429 output compatibility for transmitting information to an existing cockpit display.

Central Control Unit (CCU)

- Integrated Display (Color or NVIS)

- Diagnostic Unit

- ARINC 429 Output

- Built-in Test

- Sortie Data Storage

- High Reliability

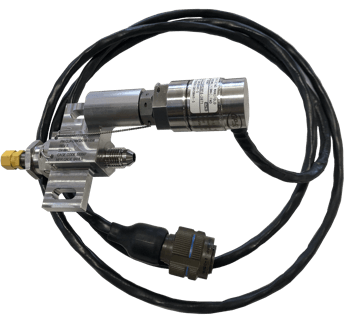

Servicing Manifold Assembly (SMA)

- Integrates Schrader Valve

- Hermetically Sealed Sensor

- No Strut Modification Required

- High Reliability

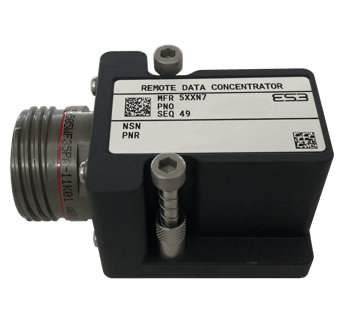

Remote Data Concentrator (RDC)

- Size, Weight, & Power Optimized (0.65 lb)

- Precise Sensor Data collection

- High Speed Data Transmission

- High Reliability

- Sensor Expansion Capability

Accuracy and reliability proven by successful operational deployment

ES3 has successfully deployed an On-Board Weight and Balance System (OBWBS). The ES3 OBWBS has been operational for more than 4 years on a fleet of 15 heavy military rotorcraft. During that time, accuracy better than plus or minus 3% gross weight has been achieved and all Reliability, Availability, and Maintainability (RAM) goals have been exceeded. The ES3 technology is not just a good concept; it is ready and proven.

Environmental Qualification Testing Pedigree

| Test Description | Military Testing MIL-STD-810* | Commercial Testing RTCA/DO-160G |

|---|---|---|

| Altitude | ✓ | ✓ |

| Temperature | ✓ | ✓ |

| High Temp Diurnal | ✓ | |

| Temp Shock | ✓ | |

| Fluids | ✓ | ✓ |

| Solar Radiation | ✓ | |

| Rain | ✓ | |

| Humidity | ✓ | |

| Fungus | ✓ | |

| Salt Fog | ✓ | ✓ |

| Blowing Dust | ✓ | ✓ |

| Blowing Sand | ✓ | ✓ |

| Explosive Atmosphere | ✓ | ✓ |

| Immersion | ✓ | |

| Waterproofness | ✓ | |

| Acceleration | ✓ | |

| Vibration | ✓ | ✓ |

| Operational Shock | ✓ | |

| Crash Shock | ✓ | ✓ |

| Bench Handling | ✓ | ✓ |

| Transit Shock | ✓ | |

| Gunfire Vibration | ✓ | |

| Acoustic Noise | ✓ | |

| Decompression | ✓ | |

| Overpressure | ✓ | |

| Chemical Decontamination | ✓ | |

| Fire | ✓ |

*Testing performed to MIL-STD-810G and/or MIL-STD-810H, based on program requirements

Electromagnetic Interference (EMI) Qualification Testing Pedigree

| Test Category | Test Section | Military Testing MIL-STD-461* | Commercial Testing RTCA/DO-160G |

|---|---|---|---|

| Conducted Emissions | CE101 | ✓ | |

| Conducted Emissions | CE102 | ✓ | |

| Conducted Susceptibility | CS101 | ✓ | |

| Conducted Susceptibility | CS114 | ✓ | |

| Conducted Susceptibility | CS115 | ✓ | |

| Conducted Susceptibility | CS116 | ✓ | |

| Radiated Emissions | RE101 | ✓ | |

| Radiated Emissions | RE102 | ✓ | |

| Radiated Susceptibility | RS101 | ✓ | |

| Radiated Susceptibility | RS103 | ✓ | |

| Audio Frequency Conducted Susceptibility | Section 18 | ✓ | |

| Induced Signal Susceptibility | Section 19 | ✓ | |

| Radio Frequency Susceptibility | Section 20 | ✓ | |

| Emission of RF Energy | Section 21 | ✓ | |

| Indirect Lightning Strikes | Section 22 | ||

| Direct Lightning Strikes | Section 23 | ✓ | |

| Electrostatic Discharge | Section 25 | ||

| Power Quality | MIL-STD-704F | ✓ |

*Testing performed to MIL-STD-461F and/or MIL-STD-461G, based on program requirements